💨 Complete Guide to the AK-III Pneumatic Tufting Gun

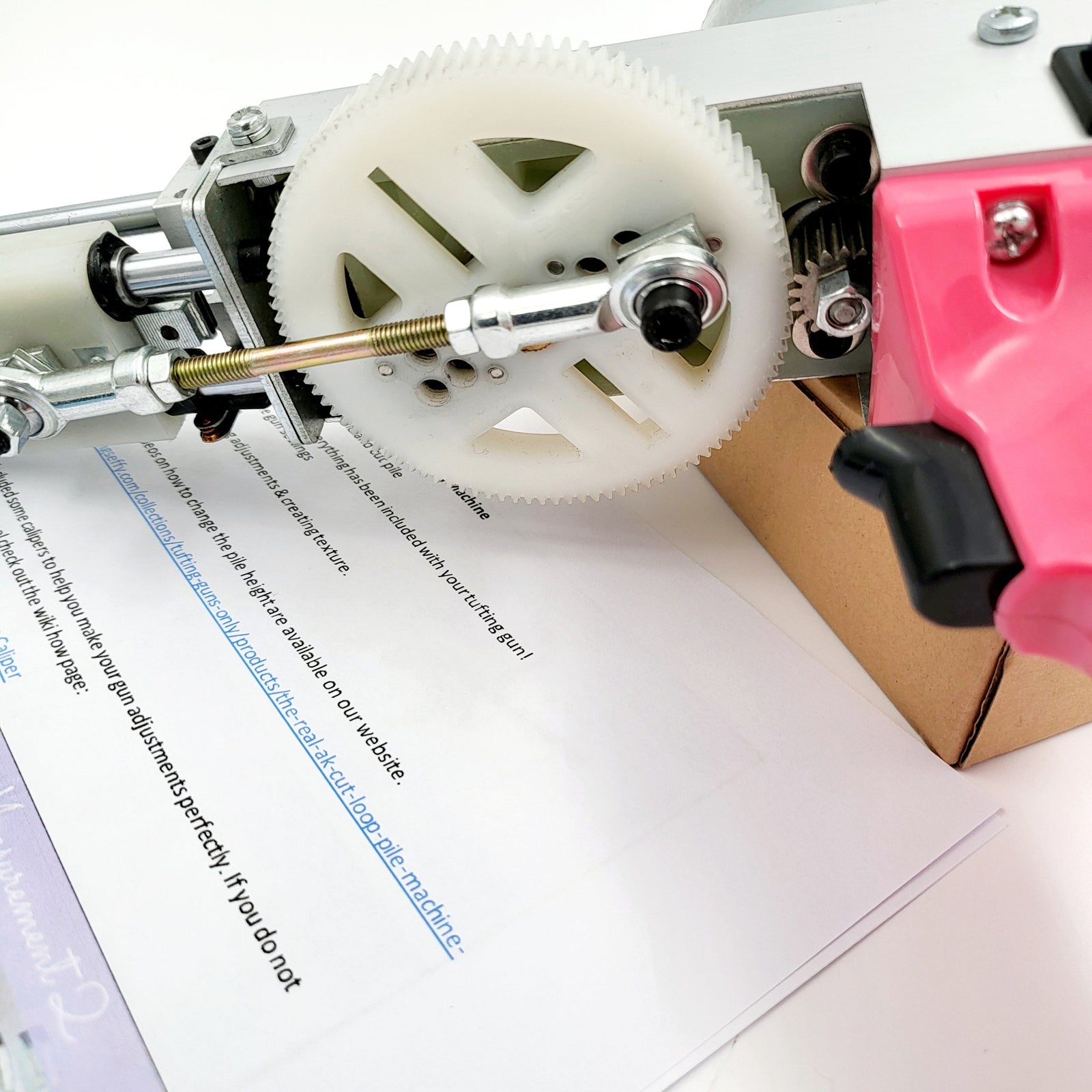

The AK-III (AK-3) is a professional-grade pneumatic tufting machine designed for long-pile, ultra-soft, sculpted, and high-texture rugs. It delivers powerful yet smooth performance and produces beautifully fluffy results — all while being surprisingly lightweight for a pneumatic tool.

Because the AK-III is a dual-powered system (electric + air), proper setup is essential. This guide explains everything you need to know to use the machine safely and effectively: choosing a compressor, understanding airflow, connecting fittings, setting PSI, adjusting blades and pile height, checking timing, and accessing all our tutorial videos.

✨ Before You Begin — How the AK-III Actually Works

The AK-III is a dual-powered tufting machine, which means it requires both electricity and compressed air to function correctly. Each power source drives a different part of the process:

- Electricity powers the mechanical components — the needles moving in and out, and the blade turning.

- Compressed air does not move the needles or blade. Its job is to push the yarn through the needle tip with consistent, even pressure.

In simple terms:

- The electric motor creates the “tufting action.”

- The airflow feeds the yarn into the fabric.

Because the AK-III depends on both systems working together, correct compressor setup and stable electrical power are essential for high-quality tufting.

💨 Air Compressor Requirements (Critical)

To operate the AK-III properly, your air compressor must meet all of the following minimum specifications:

| Requirement | Minimum |

|---|---|

| Tank Size | 15.8 gallons (60 L) |

| Airflow | 7.0 CFM (200 L/min) |

| Working Pressure | 120 PSI (8 bar) |

| Recommended | 145 PSI (10 bar) compressor |

Airflow is far more important than tank size. Most household compressors cannot reach 7.0 CFM (200 L/min) at 8–10 bar, which is why many fail when used with pneumatic tufting guns.

🔧 Example of a Suitable Compressor

AEG 60L Silent Air Compressor

(NZ/AU comparison link — U.S. customers can use it to find a similar 7.0+ CFM (200+ L/min), 10-bar silent compressor.)

🔩 Required Fittings & Hose Setup

Your AK-III tufting machine comes with a 3/8" ARO male fitting pre-installed.

To connect it to your air hose and compressor, you will need (at least for kiwis and australians - other countries' fittings may differ slightly)

- 3/8" ARO female fitting

- 3/8" → 1/4" BSP female brass reducer

- 1/4" air hose

Ensure all fittings are securely tightened — even small leaks can reduce airflow enough to cause tufting issues. Use PTFE tape.

🛢️ Protect Your Pneumatic System

To prevent moisture damage and extend the life of your pneumatic valve, we strongly recommend installing a:

Filter + Lubricatorbetween the compressor and the tufting machine.

| Component | Requirement |

|---|---|

| Filter/Lubricator | Must be rated for 140 PSI (9.7 bar) or higher |

| Oil Type | Hydraulic air-tool oil only (never general-purpose oils) |

NZ reference examples (to help you identify similar products in your own country):

Filter + Lubricator (NZ reference)

Hydraulic Air Tool Oil (NZ reference):

🔧 PSI Settings for Different Tips

The AK-III requires different PSI ranges depending on the needle/tip size:

| Tip Size | Recommended Pressure |

|---|---|

| Small–Medium Tips | 90 PSI (about 6.2 bar) |

| Large Tips | Up to 120 PSI (about 8.3 bar) |

If your compressor shows pressure in bar, you can use these approximate equivalents or Google’s PSI ↔ bar converter. Both units are widely used.

✂️ Blade Position & Foot (Canvas Shelf) Adjustment

Incorrect blade or foot height is one of the most common causes of tufting issues. Set them as follows:

🔹 Spacer Orientation

- Thin side on the left

- Thick side on the right

- (When you are facing the needle)

🔹 Blade Direction

The blade must align with the thin side of the spacer.

🔹 Foot Height

| Pile / Needle Height | Foot Position |

|---|---|

| Up to 1.6 in (40 mm) | Foot level with the needle |

| Over 1.6 in (40 mm) | Foot approx. 1/32 in (1 mm) above the needle |

This slight height difference prevents drag and allows smoother travel when working with longer needles and higher pile.

🛠️ Checking Valve Timing

Valve timing rarely becomes misaligned unless the gun head has been removed. Use this safe check:

- Connect the AK-III to your air compressor.

- Do NOT plug in the power cord.

- Manually turn the connecting rod with an Allen wrench.

When the blade passes the air hole, you should hear airflow. If the airflow does not match the blade movement, the timing may need to be adjusted.

🎥 AK-III Instructional Videos

Note: These AK-III videos were filmed in 2020 before we produced more polished tutorials. The information is accurate, but the filming style is older. Updated AK-III videos are being created for 2026.

🔹 Understanding Air Compressors (Beginner-Friendly)

https://youtu.be/tpe4prO1B7U

🔹 How to Attach Your Air Hose

https://youtube.com/shorts/PHMScMooP5Y

🔹 How to Change from Cut Pile to Loop Pile

https://youtu.be/cEiagUdD890

🔹 How to Change the Feeding Wheel Size

Full version: https://youtu.be/Ox9r_myQEzM

Short version: https://youtube.com/shorts/EYIRK-g149E

📋 Final Tips

- Check all hose connections for leaks before tufting.

- Let your compressor fully refill the tank for consistent airflow (7.0 CFM / 200 L/min where possible).

- Confirm blade and spacer alignment before every session.

- Use only hydraulic air-tool oil in your lubricator.

- Always match PSI to your needle/tip size (e.g., 90 PSI / 6.2 bar vs. 120 PSI / 8.3 bar).

- Keep the gun clean and free of yarn fluff inside the head.

✨ Final Thoughts

The AK-III is one of the most powerful and versatile tufting machines available. With the right compressor and correct setup, it delivers exceptionally smooth, consistent performance and beautifully fluffy long-pile results.

If you need personalised recommendations or troubleshooting support, email us anytime at hello@allthingseffy.com.